Model of the Exomars rover : the drill unit takes shape

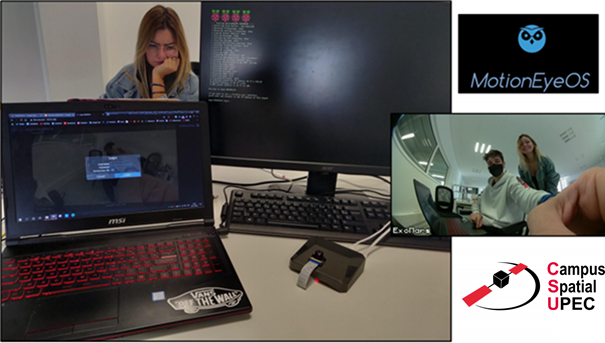

Camille Petton and Nathan Menuat, two ICAM students involved in the Rover project of the UPEC Space Campus

After six months of work, the integration of the drill unit began thanks to Camille Petton and Nathan Menuat, two engineering students from ICAM in Sénart (France).

“We had to use tricks and find techniques to imitate reality.” Nathan Menuat and Camille Petton worked for six months to replicate the ExoMars drill as closely as possible with commercially available components. The two students from ICAM School of Engineering in Sénart (France) take part in the multidisciplinary project of the Space Campus of the University Paris Est Créteil (CSU). With students from other graduate schools and universities, they build a functional and actual-size model of Rosalind Franklin space exploration vehicle. This ambitious challenge gives them the opportunity to learn professional skills in aerospace industries.

The Space Campus will use the model to explain the functions of the Rosalind Franklin rover to non-scientists in France. The space exploration vehicle was developed by the European Space Agency and the Russian Roscosmos, and it is named after an English chemist, who played a crucial role in understanding the molecular structures of DNA. His task will be to look for life traces on the red planet from 2023. A key date for the Space Campus, which wants to deploy the model on the day of the landing of the real Exomars rover on Mars.

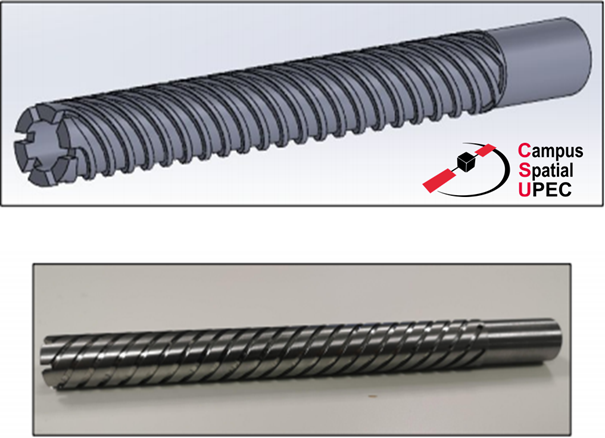

The central role of the « drill bit »

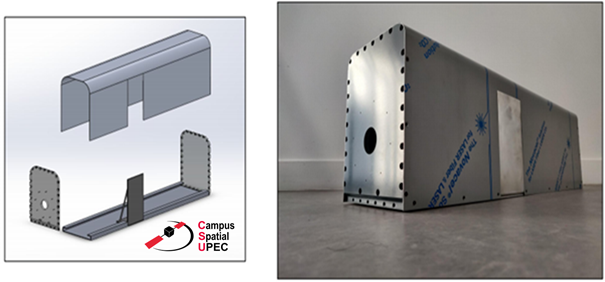

To know whether life ever existed on Mars, the rover will acquire soil samples down to a maximum depth of 2 meters at a speed of 5 millimeters per minute. Each drilling will last around three days. “But our model can do it faster, because it has an educational purpose, says Camille Petton. The drill bit will have a speed of 1200 revolutions per minute, and it will dig down five centimeters in a few seconds.” The tool will be actuated by a specific motor. “It’s a hollow motor, says Nathan Menuat. So a piston will be able to push the soil sample inside the rover.” The motor will be fixed to a steel plate and it will be protected by a metal housing named “crankcase”.

Camille Petton and Nathant Menuat plan to cover it to imitate the appearance of the ExoMars space exploration vehicle. The two students also reproduced parts of the rover with 3D modeling techniques, and they bought fake cables. They decided that the model will dig plaster because this material is easy to drill.

The drill will be controlled via internet

The two engineers worked on reproducing the movements of the drill too. “First it will be positioned above the drill site, says Nathan Menuat. Then, the drill bite will take a sample of soil, which will be analysed inside the rover.” The model will be able to raise, lower and turn the drill, to raise, lower and turn the drill bit and to push the sample inside the rover.

After six months of work, when we ask the two engineers what was the most difficult task of the project, their answer is clear : the drill bit. “We didn’t find a grinding tool which had the required dimensions. So we choose to produce it ourselves.” Camille Petton is showing the drill bit with six blades. “We carried out at least five tests to get this piece.” The two engineers designed the tool, and younger ICAM students built it. The latter will construct the structure of the rover with a third team of ICAM engineering students, who began to work on the project in February. “Next students will continue the rig-up of the drill, she says. We told the school administration that they should feel comfortable with coding, because it will represent an important part of the work.” Before Nathan Menuat and Camille Petton, a first group of students worked six months on the ExoMars drill and did literature review.

The functional model of the Rosalind Franklin rover is a project lead by the UPEC Space Campus, co-financed by the Île-de-France Region as part of its program to support the dissemination of scientific, technical and industrial culture (“Science for all “) and CNES.

Mathilde Pires

Journalism student at the CFJ

One Response

Once the rover has reached a scientifically interesting objective, for example, a sedimentary rock outcrop that could have been deposited in an aqueous environment, PanCam WAC, PanCam HRC, and ISEM can work in a concerted manner to study the target. This characterization can be used to determine which portion of the outcrop to investigate at very high resolution with CLUPI, the close-up imager accommodated on the ExoMars drill. PanCam can also support rover operations when performing subsurface scanning maneuvers. These are predefined trajectories executed by the rover in order to construct 2-D and 3-D models using the WISDOM Ground Penetrating Radar (GPR) and the ADRON neutron detector. They allow the determination of, respectively, the subsurface stratigraphy under the rover (including the existence of potential obstacles) and the subsoil’s level of hydration both important for deciding where to drill.